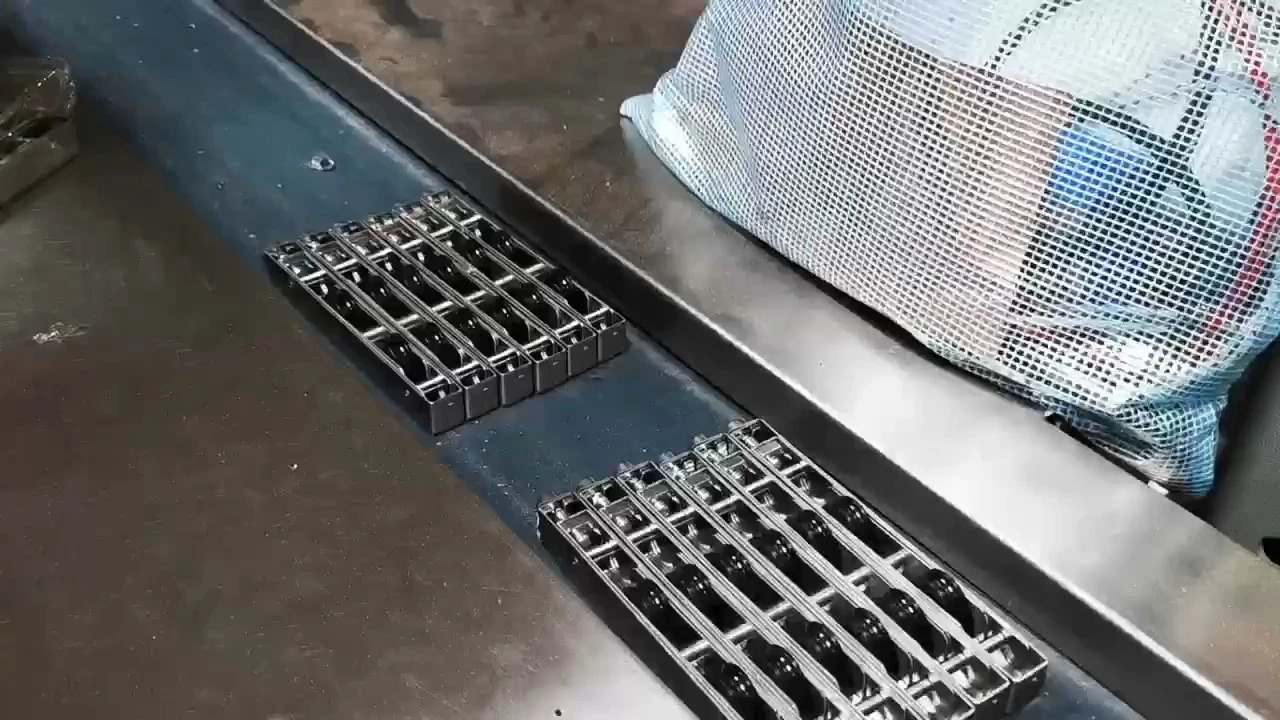

Metal Window and Door Roller Sliding Pulley for Shower Room

Here's an English overview of the key structural components of a typical metal door/window single roller (also known as a single roller wheel or sheave):

-

Roller Wheel: The core rotating component, usually made of durable material like nylon, polyamide (PA), or sometimes steel with a rubber tread. This is the part that directly rolls within the track.

-

Wheel Axle/Bearing Pin: A hardened steel pin running through the center of the roller wheel. It provides the axis for the wheel to rotate.

-

Bearings: Located between the roller wheel and the axle/bearing pin. Common types are:

-

Ball Bearings: Small steel balls held in a race, providing smooth, low-friction rotation. Most common in quality rollers.

-

Bushings/Sleeve Bearings: Simple cylindrical sleeves (often bronze, sintered bronze, or polymer) that the wheel rotates around the pin on, usually with grease lubrication. Simpler and potentially less smooth than ball bearings.

-

-

Bracket/Housing/Mounting Frame: The structural metal component that holds the wheel assembly. It typically features:

-

Mounting Holes: For attaching the roller securely to the bottom corner of the door or window leaf (sash) using screws or bolts.

-

Axle Support Points: Where the wheel axle/bearing pin is fixed or pressed into place.

-

-

Anti-Derailment Lip/Flange (Optional but common): A raised edge or lip on one or both sides of the bracket/housing. This lip fits under the edge of the track, helping to prevent the roller from accidentally jumping out (derailing) if the door/window is lifted or subjected to lateral force.

-

Height Adjustment Mechanism (Optional but common): Found in many modern rollers, especially for doors. This allows fine-tuning the roller's height relative to the bracket, enabling the installer to level the door or window and ensure smooth operation within the track. It often involves a threaded screw or eccentric cam acting on the wheel axle.

-

Lubrication (Internal): High-quality rollers often have factory-applied lubricant (grease) sealed within the bearing area to ensure smooth, long-lasting operation.

Typical Material Combinations:

-

Bracket/Housing: Steel (often galvanized, zinc-plated, or stainless steel - e.g., 304/316 for corrosion resistance), Zinc Alloy (Zamak).

-

Roller Wheel: Nylon, Polyamide (PA), POM (Acetal/Delrin), Rubber-coated Steel.

-

Axle/Bearing Pin: Hardened Steel, Stainless Steel.

-

Bearings: Steel balls/chrome steel (ball bearings), Bronze, Polymer (bushings).